PARAMETER:

| Effective width | 300MM 1600MM 1800MM (Optional model width) |

Slitting width | 0-1800MM |

| speed | 300M/MIN | Slitting speed | 300M/MIN(Longitudinal slitting) |

| Unwinding diameter | 600MM | Unwinding lock | 3"- 6"Internal expansion type mechanical chuck |

| Unwinding tension |

5-50KG,640N.M Air friction tension brake

Automatic taper tension control

|

Winding diameter | 2*600MM |

| Winding lock | Air friction slip shaft | Winding tension |

Automatic taper and dynamic

Synthetic tension control

|

| Main motor | 5.5KWThree-phase AC motor | Winding motor | KWThree-phase AC motor |

| Total power | 20KW | Correction range | 50MM(Precision±0.5MM) |

|

Working power |

AC380V Three-phase five-wire power supply380V±10% 50HZ±5% |

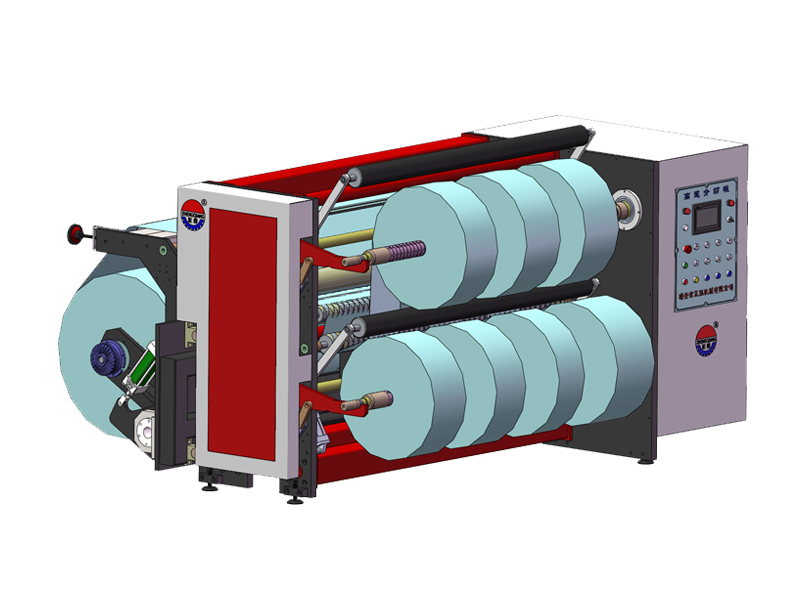

Dimensions | long:3100mm width:3200mm high:2000mm |

| weight | About3000KG | Applicable material |

Various types of 50-300g/m2 reel self-adhesive paper, paper-plastic composite, optical film, electronic film, self-adhesive, protective film, paper and other materials |

Main configuration:

|

Unwinding function: The unwinding of the machine adopts the function of shaftless feeding, and the pneumatic top is tight.

The linear correction platform is used to position and slide the linear guide.

Unwinding mechanical shaft ¢ 3", ¢ 6", no shaft.

Correction system: EPC ultrasonic correction system is adopted.

Tension control: Taper automatic controller PLC joint control.

Balance adjustment: equipped with a hand-adjustable left and right tension balance slider.

|

Winding function: The machine adopts the cantilever method, and the other end adopts a pneumatic support large arm, which can meet the winding work of various materials, and has the convenience and quickness of discharging.

The winding motor adopts the slip shaft to perform taper automatic tension control by PLC.

The winding power transmission adopts arc tooth synchronous belt transmission.

Support arm: pneumatically executed.

Pressure arm: constant pressure arm.

|

|

Traction system: Traction drive: PLC automatic control motor drive.

Traction roller set: Dingqing traction rubber roller, antistatic material, hardness Shore 65o-70o 1

The traction combination enhances the film transport capability and effectively blocks unwinding tension and take-up tension.

|

Cutter system: This machine is equipped with a round knife and a straight knife device (optional)

Knife depth fine adjustment device

Tool holder support shaft

Tool holder 10

|