Scope of application

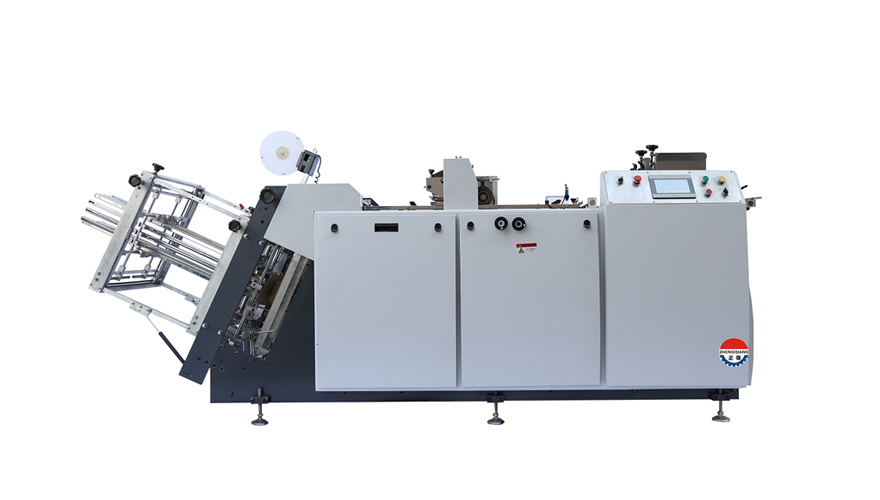

The three-dimensional carton machine is a special molding machine that can produce hamburger boxes, square boxes, food boxes, fast food boxes, French fries boxes, etc. Carton made of cardboard and corrugated paper is more environmentally friendly than plastic boxes.

Performance and Characteristic

1.One machine can produce a variety of different products, and the time for changing the mold is short.

2.The machine is controlled by the PLC intelligent system and can produce complex boxes.

3.Can automatically collect, stack, and count finished products.

4.Low noise, low wear parts, high environmental protection.

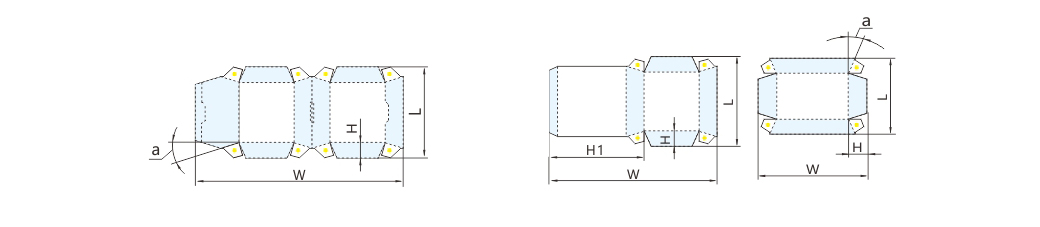

Process carton size

Process carton size

| Model |

|

800 |

1000 |

| Blank length |

L |

100-450mm |

100-450mm |

| Blank width |

W |

100-580mm |

100-400mm |

| Height of side flaps |

H |

15-200mm |

15-200mm |

| Height of side flaps+lid |

H1 |

50-200mm |

50-200mm |

| Conicity |

a |

5°-40° |

5°-40° |

Standard output

A: Uncovered square box Maximum output: 180/min

B: French fries box Maximum output: 150/min

C: hot dog box / hamburger box Maximum output: 120/min

D: Food box Maximum output: 100/min

Main technical data

| Model |

ZQCX-800 |

| Bonding method |

(Max.180 pcs/min)

(According to the box shape and different speed) |

| Max packaging capacity (according to the shape of the box) |

Water-based glue (hot melt adhesive device-paid option) |

| Raw materials |

200-600g / square meter (white cardboard, corrugated paper) |

| Corrugated paper/ paper thickness |

(Max. 1.5mm) |

| Electrical requirements |

4.5kw/hour |

| Air source requirements |

(6kg/cm2×200L/min) |

| Overall dimensions (L×W×H) |

3000 ×1450×1300mm |

| Weight |

2000kg |